| Product | Grade | Description | Image |

| Formic acid | 99% | Synthesis of formic acid from carbon dioxide We are currently carrying out this project by receiving the CCU formic acid manufacturing process and related catalyst manufacturing technology from the Korea Institute of Science and Technology and Kookmin University. After verifying the manufacturing of formic acid, we plan to commercialize the facility by 2030 to manufacture approximately 40,000 tons of formic acid per year. Through this, we aim to reduce carbon emissions by 40,000 tons per year and meet domestic demand for formic acid industrially. Furthermore, we aim to enhance national competitiveness by developing overseas sales networks. |

|

| Poly carbonate | - | Synthesis of polycarbonate from carbon dioxide Through joint research with other organizations, we are conducting research to synthesize high molecular weight polycarbonate resin by utilizing it in the final polycarbonate manufacturing polymerization process from carbon dioxide. There is a difficulty in controlling the conditions of high temperature, vacuum, and ultra-high viscosity during polycarbonate polymerization, but we aim to take the lead in carbon reduction through successful process development. |

|

| Catalyst recovery | Li, Ni | Recovery of valuable metals from spent catalysts Resource circulation is attracting a lot of attention not only in Korea, where natural resources are scarce, but also around the world as a way to become carbon neutral. To this end, Patech is developing a technology that can recover high-value-added valuable metals from waste catalysts after their lifetime, convert them into high-purity chemicals, and recycle them by regenerating waste catalysts with catalysts for the same purpose. Ultimately, based on this study, we aim to enter the field of recovering valuable metals such as lithium and nickel from waste secondary batteries in the future. |

|

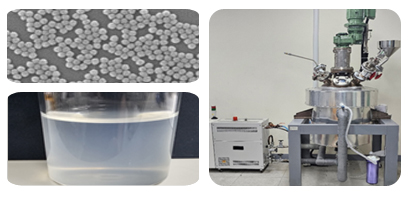

| Colloidal silica | - | Colloidal Silica Manufacturing The semiconductor industry is currently developing at a rapid pace, and its growth is expected to be even more pronounced due to the AI industry. High-purity colloidal silica, which is used as an abrasive for wafer polishing in the semiconductor process, is currently not produced domestically, and most of it is imported from Japan, the United States, etc. At Patek, we are conducting research on manufacturing high-purity colloidal silica using the sol-gel method, and are currently in positive product evaluations with several domestic customers. |

|